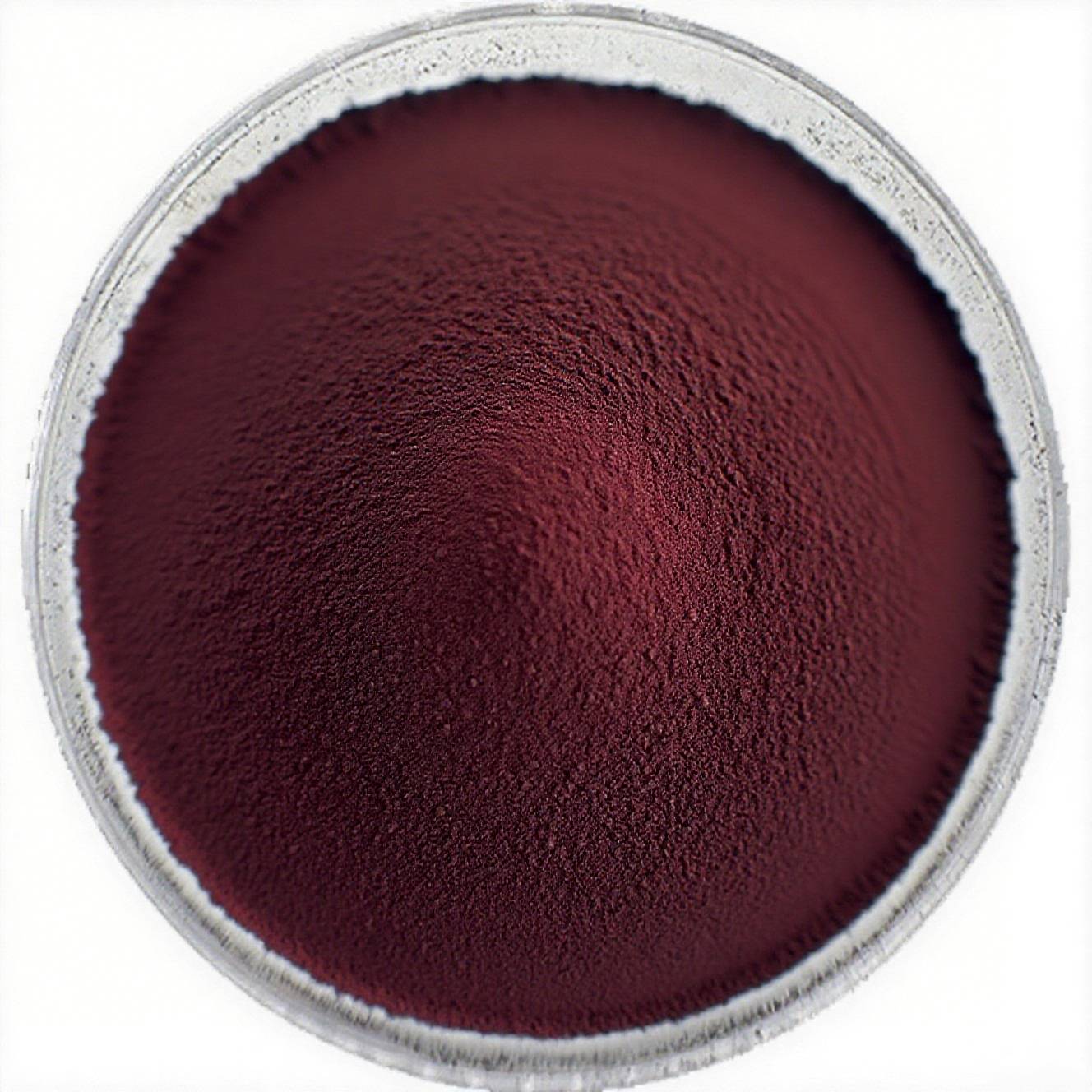

Micronized Iron Oxide Pigments

Micronized iron oxide pigments are manufactured by grinding synthetic or natural iron oxide using ultra-fine grinding equipment to a fineness of less than 5µm. For synthetic iron oxide, this process is essentially a grinding process designed to break up aggregates and agglomerates. Because micronized iron oxide can increase tinting strength by 5% without changing hue, is easily dispersed, produces high-gloss paint films, and prevents settling, floating, and clogging in the application system, it is widely used internationally.

Bayer's commercial production consists almost entirely of iron oxide red, most iron oxide yellow, and some iron oxide black.

Depending on the needs, a certain amount of surfactant (dispersant, anti-settling agent, dispersion stabilizer, etc.) is added to the iron oxide during micronization. This is one method of producing easily dispersible iron oxide pigments, which have a dispersibility of 7.0 on the Hegmann scale. The dispersibility of iron oxide pigments depends not only on the manufacturing process but also on post-processing (drying, grading, grinding, etc.). Because the crystal particles are coated in dispersants and anti-settling agents, they achieve excellent dispersion and prevent pigment settling.

- Head Office Address: No. 1 of Lane 185, South Anxie Road, Jiading District, Shanghai, China

- WeChat: 18217101261

- WhatsApp: +86 18217101261

- E-mail: pigment@shshenhong.net