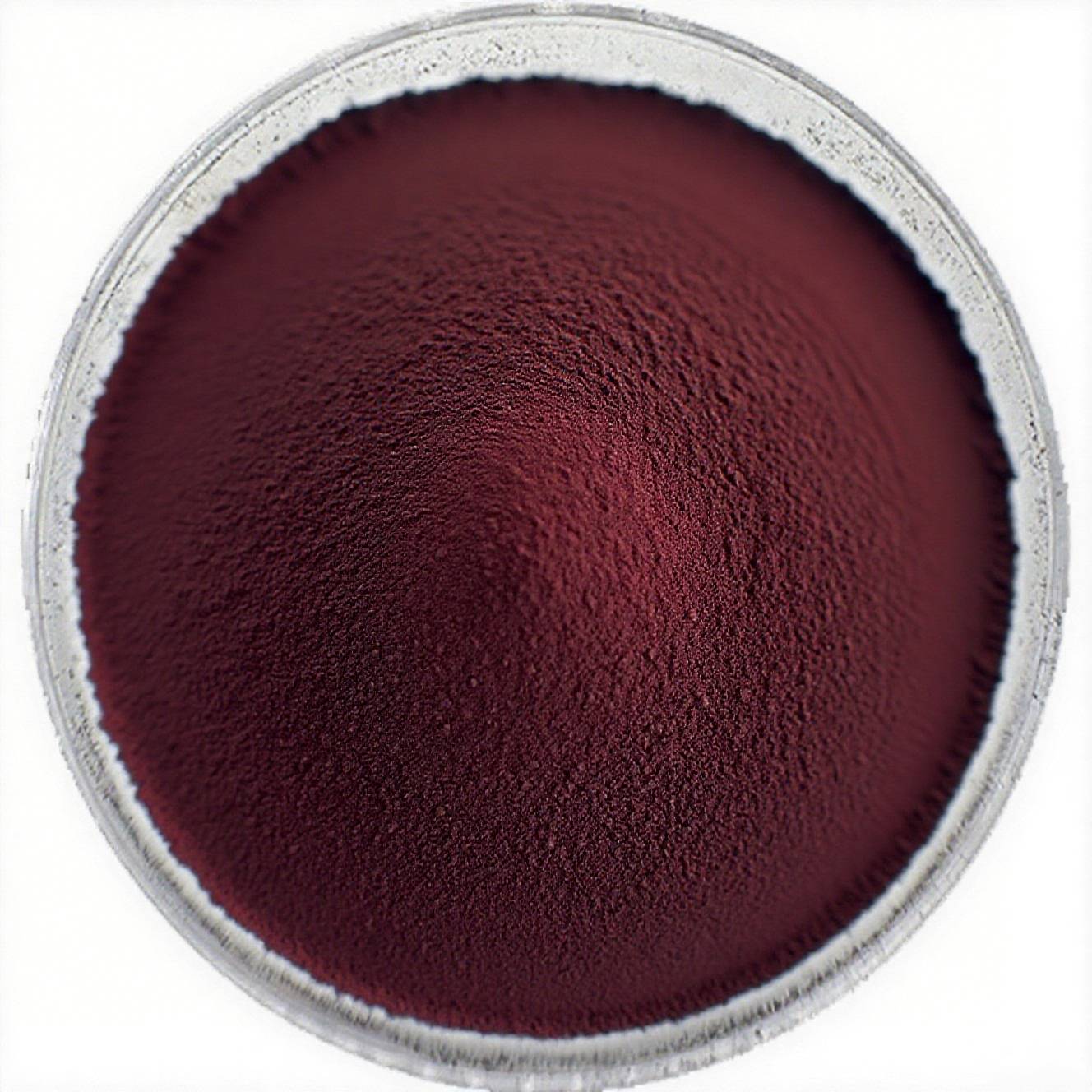

Iron Oxide Pigments for Cement and Building Materials

2020-02-18 09:25:01

1. Features

Beautiful color, excellent durability, resistance to strong sunlight and climate, alkali resistance, mortar resistance, etc., without compromising cement properties. Strong tinting strength, suitable particle fineness and structure, and good dispersibility.

2. Applications

Suitable for coloring the following building structures and cement products: Various indoor and outdoor colored concrete surfaces and building surfaces, such as walls, floors, floor tiles, roof tiles, panels, gutters, blocks, towers, colored mortar, etc.; Colored facing bricks and ridge tiles; Terrazzo and mosaic tiles for decorating indoor and outdoor walls, floors, stairs, porches, and passageways; Artificial rock, such as artificial marble and artificial limestone; Asbestos cement for decorating wallboards, floor tiles, roof tiles, window sills, and stairs.

Because iron oxide pigments offer excellent weather resistance, alkali resistance, and light resistance—properties not possessed by other inorganic or organic pigments—they are used as coatings and colorants in building materials, such as wall coverings, artificial marble, terrazzo flooring, and the coloring of silicate products. Iron oxide yellow is used to color cement or concrete pavements on runways and temple exteriors, while iron oxide red is used for surface decoration of palace walls.

3. Usage

The usage of iron oxide pigments in concrete products is limited to 1-10%. Exceeding this limit will reduce the mechanical strength of the product. Generally, a usage of 5-8% is appropriate. A lack of lead oxide and zinc oxide can affect setting time and strength. Concrete products sometimes require hot pressing and curing at temperatures above 200°C. Therefore, black and brown iron oxides, which convert to red iron at 180°C, must undergo heat stabilization. If used on terrazzo, the base layer should be 2-3 cm thick, and the top layer should be 15 cm thick.

For more information about Shenhong Pigment's iron oxide pigments and cooperation opportunities, please contact us via the following channels:

- Head Office Address: No. 1 of Lane 185, South Anxie Road, Jiading District, Shanghai, China

- WeChat: 18217101261

- WhatsApp: +86 18217101261

- E-mail: pigment@shshenhong.net